Electroless nickel plating as a source of inspiration

Electroless nickel surface treatment inspires technical solutions for large-scale projects, such as the construction of the world's largest telescope.

This surface treatment also contributes to contemporary artistic creations.

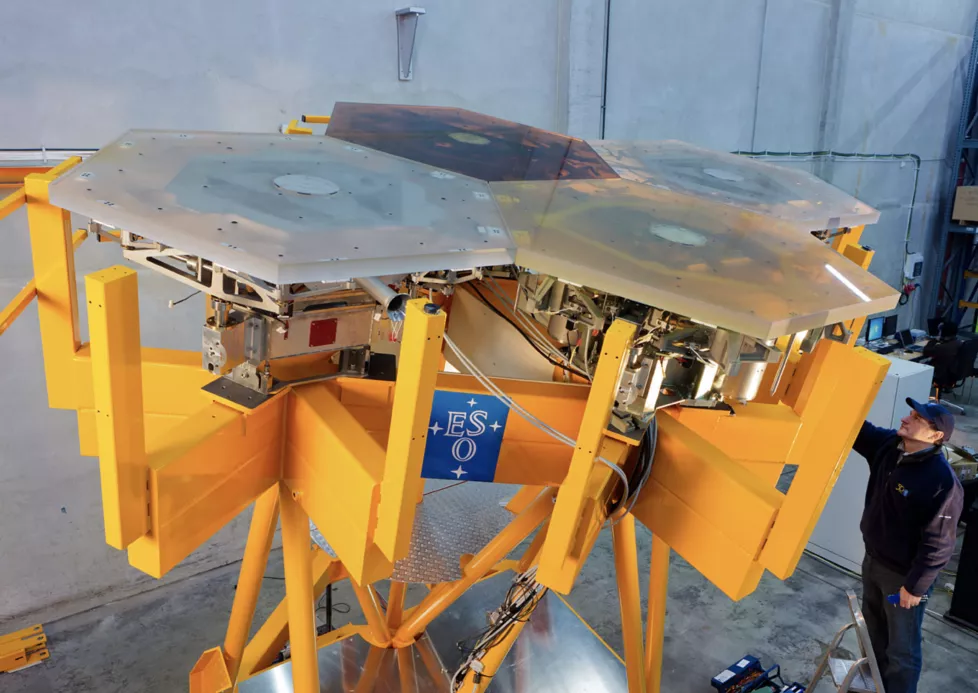

The advantages of electroless nickel plating can play a critical role in some large-scale projects. For example, the European Southern Observatory (ESO) is currently building the world's largest ground-based telescope (ELT), due to open in 2025. This will pave the way for major advances in astronomy with its 39-metre diameter primary mirror.

Electroless nickel plating is being used to enhance the technical properties of the structures that will support the hexagonal mirror segments. These segments will form part of the ELT's main mirror, which will have a total of 798 segments when completed.

Who hasn't heard of his artificial excrement producing machine ‘Cloaca’. This piece is a critique on capitalist society, wherein we produce more only to destroy more.

But the artist also enjoys resonating with medieval history and working with craftsmen to produce high-quality work. For example, he was inspired by a number of cathedrals in creating a series of steel ‘gothic trucks’.

Some of his exhibited works have been treated with electroless nickel, thereby enhancing their durability.

David Mach is a Scottish artist. He is internationally renowned for, among other things, his piece ‘Spaceman’, a gigantic 2.5 meter-high sculpture made from hundreds of standard metal clothes hangers, welded together around a plastic structure that was later removed, all protected by a layer of electroless nickel.

Autocatalytic nickel plating was used to protect the masterpiece from corrosion. It was exhibited at the Palais-Royal in Paris.

(*) Electroless Nickel Plating, Prof. Dr.-Ing. Dr. habil. Nasser Kanani, p. 5. Source: Galvanotechnik 91 (2000), No9, p. 2504.