Electroless nickel plating

What is electroless nickel plating?

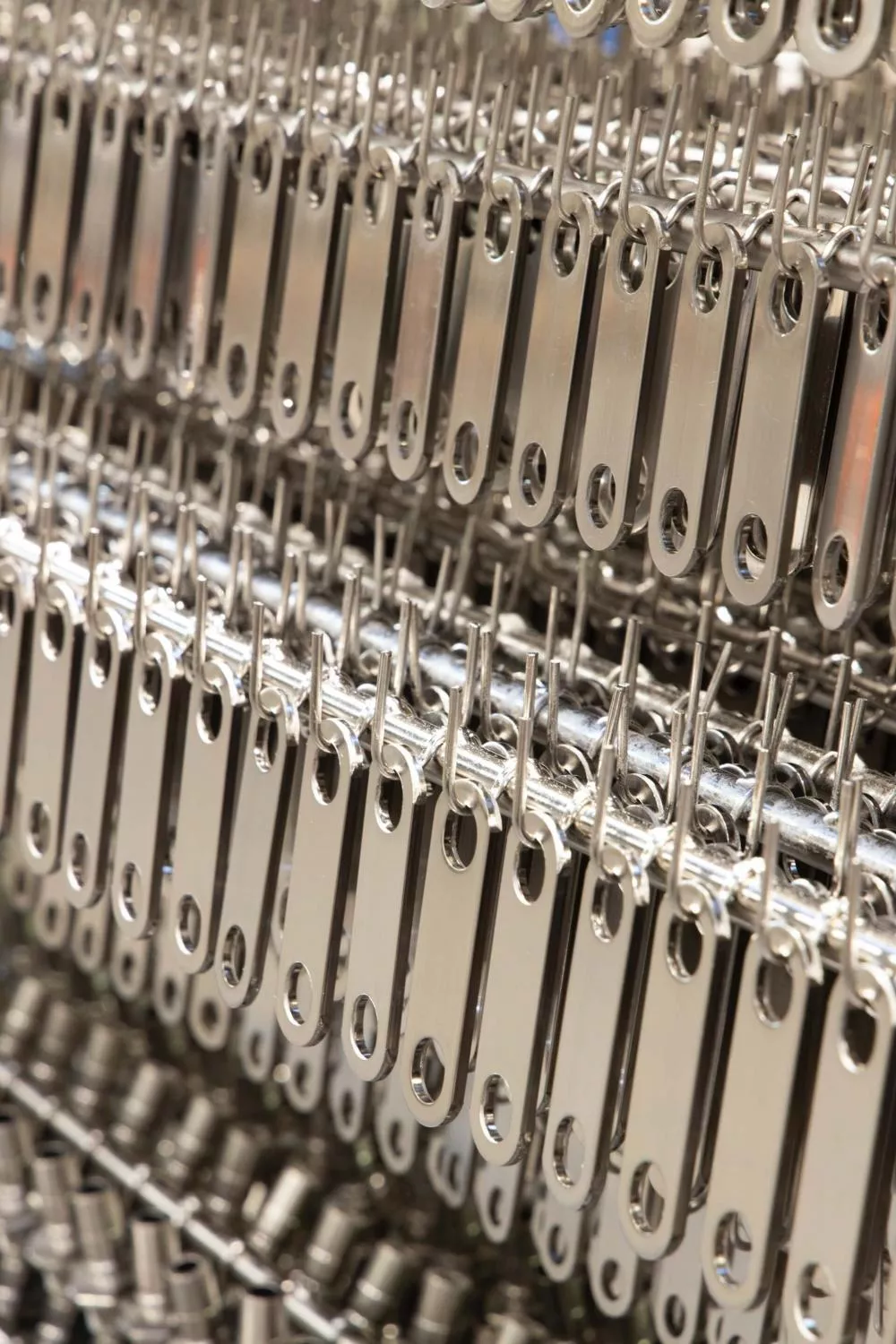

Electroless nickel plating is a metal surface coating process that involves depositing a thin layer of nickel on a metal surface. It is a nickel-phosphorus alloy (9 to 12 wt%) that is applied using a chemical process by immersion in an aquatic environment. It imparts new properties to the treated surfaces and is used, among other things, to improve the corrosion resistance and wear resistance of metal parts.

Unlike all electrolytic processes, the chemical nickel plating process enables your steel, copper, aluminums, … parts to be given an absolutely uniform and precise deposit with no edge effects. This type of surface treatment is particularly suitable for producing complex, variable-geometry parts. It does not require any finishing after surface treatment and respects the tolerances of the part.

Protection Against Corrosion

The P content of >8.5 wt% gives the Kanigen® electroless nickel layer its amorphous structure and excellent resistance to corrosion. Different results can be achieved depending on the layer thickness.

Anti-Static Applications

This anti-static property is valued, for example, in frames and mechanical parts in the production of semiconductors.

Amorphous

This amorphous character makes electroless nickel plating particularly suitable for vacuum applications.

Reduced Friction

Electroless nickel greatly reduces adhesive wear and is also used to avoid cold welds.

We offer different variants of the process by adapting :

Phosphorus content

The content of phosphorus has an impact on the structure of the deposit and adds different specific properties to the treated part:

- hardness as deposited

- protection against corrosion

- magnetic behavior

The surface treatments applied by the group are :

- Kanigen® electroless nickel deposits (9-12 wt%P)

- low phosphorus electroless nickel deposits (1-3 wt%P)

- non-magnetic high-phosphorus electroless nickel deposits (10.5 wt%P)

- ...

(*) wt%P = phosphorus content

Heat treatment

Heat treatment influences the surface coating:

- improved adhesion

- enhanced hardness and wear resistance

- reduction of hydrogen embrittlement(steel > 1000 MPa)

The surface treatments applied by the group are :

- Hard electroless nickel (280°C)

The relatively low temperature of this heat treatment has no impact on the precision of the part. - Diffused electroless nickel (650°C)

The composition of electroless nickel

By adding third party elements such as PTFE, ternary and quaternary coatings are deposited which change the properties of the coating. This type of surface treatment is only applied at our site in Belgium, where we specialize in PTFE electroless nickel plating of parts. This deposit consists of a Kanigen® electroless nickel plating undercoat, the thickness of which can vary depending on the corrosion protection required, followed by a co-deposition layer in which the PTFE is homogeneously integrated, with a V% of 20% to 30%. The deposition of this co-deposition layer improves friction resistance.

The surface treatments applied by the group are :

- Electroless nickel with PTFE (duplex dispersion deposition)

By applying a heat treatment, an improvement in hardness can be obtained without any reduction in friction.

Other electroless nickel duplex deposits

Other variants can be created by combining different layers that have electroless nickel plating as an undercoat:

- Matt black electroless nickel

- Low phosphorus electroless nickel on aluminium

Corrosion resistance of electroless nickel

The quality of Kanigen® electroless nickel plating comes from its phosphorus content (>8.5 wt% P), which renders the raw X-Ray layer amorphous, thereby providing excellent corrosion resistance.

Excellent results can be achieved by increasing the layer's level of thickness.

Corrosion resistance according to the ISO 9227 ‘neutral salt spray test’:

| Limited resistance | 2 μm to 10 μm | 12 hours |

| Medium resistance | 10 μm to 25 μm | 192 hours |

| High resistance | 25 μm to 50 μm | 480 hours |

| Very high resistance | > 50 μm | 960 hours |

Technical properties of electroless nickel

| Melting point | 890°C |

| Expansion coefficient | 13 x 10-6 cm / cm °C |

| Thermal conductivity | (10.5 wt% P) = 0.016 cal.cm-1s-1grad-1 |

| Electrical resistance | 50 to 60 μΩcm |

| Contact resistance | 30 mΩ |

| Magnetisability (9 wt% P) | 4% |

| Ductility | 2,2% to 6% |

| Hardness as deposited | 530 HV0,1 |

International standards for electroless nickel plating

These treatments are carried out according to the European standard ISO 4527 (replacing the German DIN 50966, Japanese JIS H8645 and French AFNOR NF A91-105) or the American standard ASTM B733.

AMS standard 2404 (replacing AMS-C-26074 and Mil-C-26074E) can equally be applied in an aeronautical or military context.

Other standards can be followed on request.

Treated Materials

The electroless nickel plating process makes it possible to treat a broad spectrum of materials used within the industry. Kanigen Group primarily treats carbon, alloyed and stainless steels, cast iron, aluminium and copper alloys, etc., along with other more special materials such as silver (Ag), INVAR, 17-4PH, etc.

In recent years, we have specialised in the processing of all grades of aluminium, including not only the 1000, 2000, 3000, 5000, 6000 and 7000 series, but also die-cast and injected aluminium, with the exception of ZAMAK alloys.

Treatments are carried out in barrels, rack-plated or with dedicated fixtures. If appropriately designed and prepared, welded parts can also be treated.

Electroless nickel and its variants

YES, I would like to receive more information regarding Kanigen Group’s technical solutions

Download the data sheet