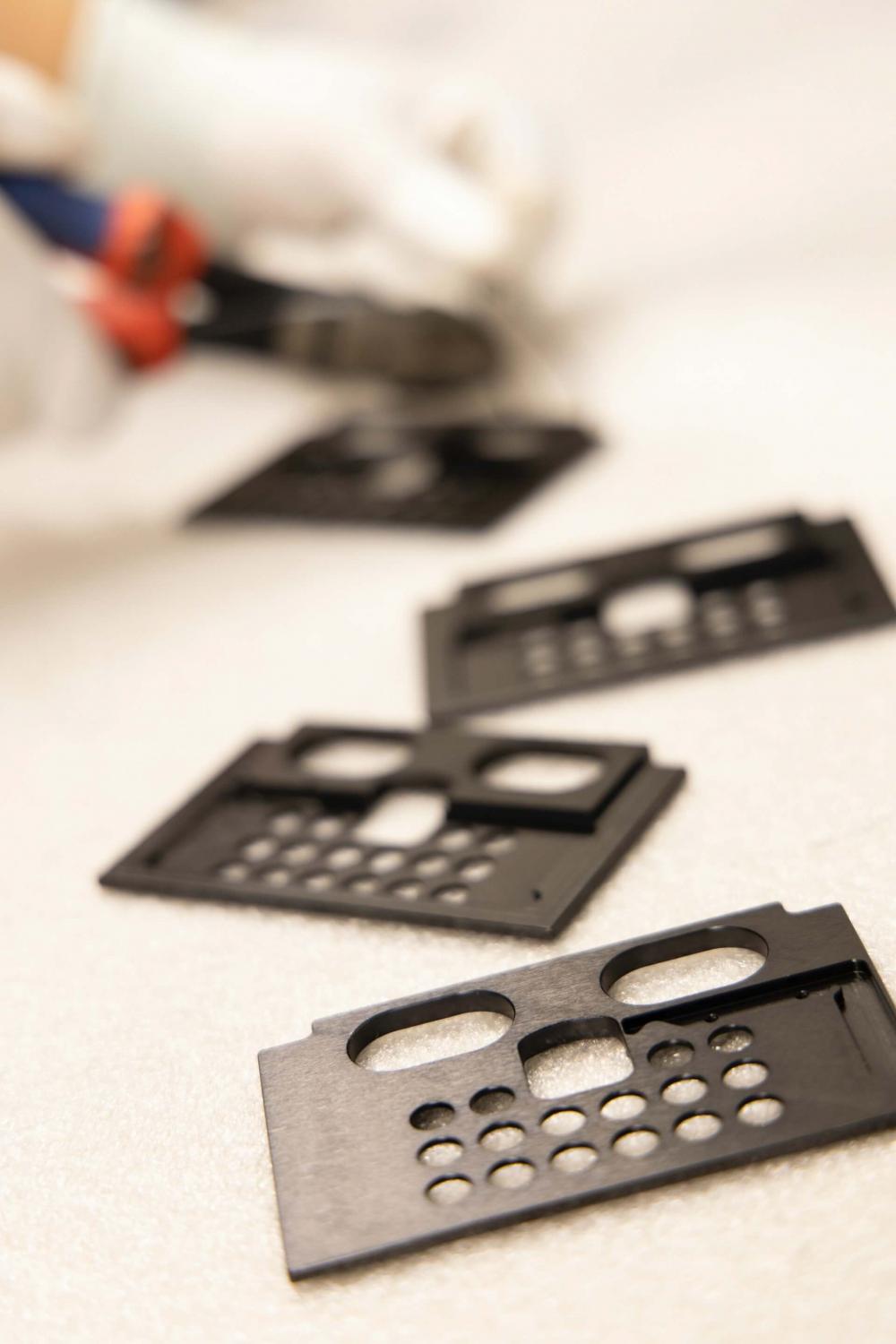

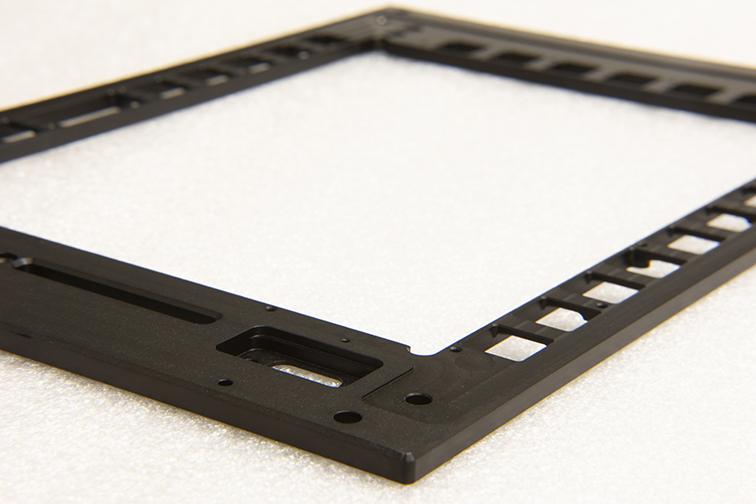

Black electroless nickel

Black electroless nickel plating consists of a Kanigen® electroless nickel layer, followed by a second layer with a specific wt% P composition. This layer is then passivated, giving it a matt black appearance.

Optical Applications

Matt black electroless nickel (22 on the L.A.B. scale)

This layer, perfectly black and matt, without irrisation, combined with a high phosphorus electroless nickel coating, allows us to serve markets in search of a visual aspect combined with specific chemical, mechanical and optical (absorption and emission) properties.

Processed Materials

The electroless nickel plating process makes it possible to treat a broad spectrum of materials used within the industry. Kanigen Group primarily treats carbon, alloyed and stainless steels, cast iron, aluminium and copper alloys, etc., along with other more special materials such as silver (Ag), INVAR, 17-4PH, etc.

In recent years, we have specialised in the processing of all grades of aluminium, including not only the 1000, 2000, 3000, 5000, 6000 and 7000 series, but also die-cast and injected aluminium, with the exception of ZAMAK alloys.

Treatments are carried out with dedicated fixtures/racks or hang-plated but cannot be barrel plated. If properly designed and prepared, welded parts can also be treated.

Corrosion Resistance

Corrosion resistance is defined by the Kanigen® electroless nickel undercoat, the thickness of which can be adapted according to the customer's specification.

Technical Properties

- Colour matt (22 on the L.A.B. scale)

- Homogeneous and uniform appearance

- Repeatable and without iridescent effect

- Layer hardness: 8H (pencil hardness)

- Scratch sensitive

- Parts cannot be barrel treated.

- To be used for static parts.

- UV stable

- Good UV absorption and IR emission

- Good corrosion resistance

Total Integrated Reflectance 300-3000 nm

Green: light reflection on black Kanigen® electroless nickel

YES, I would like to receive more information regarding Kanigen Group’s technical solutions