Industry

Protection against corrosion

Wear-resistant

Non-magnetic

Reduced friction

Solderability

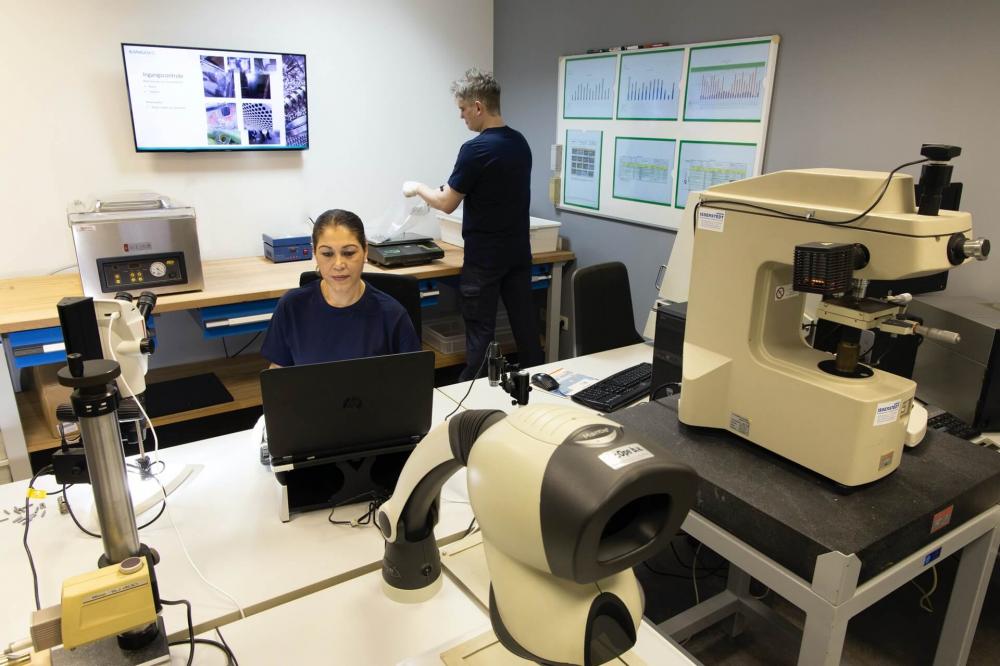

Electroless nickel and Electroless Nickel with PTFE (NiPtef) are being increasingly applied on mechanical parts, where geometries are becoming more complex, requiring even greater precision.

References: Schneider, Le Gris, Parker, Stäubli, Eaton, etc.

Applications:

- Connectors

- Plugs

- Push buttons

- Circuit breakers, etc.

Electroless nickel has been applied in compressor and pneumatic designs for years, both on high-precision machine core parts and on air inlet and exhaust piping.

The advantage of electroless nickel is that it deposits a uniform layer inside tubes and pressure vessels. Electroless nickel with PTFE is mainly used in safety systems or for dry lubrication.

References: Atlas Copco, Siemens Energy, etc.

Applications:

- Compressor components

- Pressure regulators

- Connectors

- Pressure vessels, etc.

Electroless nickel and hard electroless nickel are both applied in solving corrosion or wear issues. In the case of differentials, hard electroless nickel is also applied to prevent galling between two components.

References: Caterpillar, CNH, John Deere, Dana, etc.

Applications :

- Valve spools

- Train breaking systems

- Biofuel supply pipes

- Differential components

- Hydraulic system components, pistons, hydraulic manifolds, connectors

- Coupling between metro/train wheels and motors, etc.

Due to their corrosion resistance and hardness, electroless nickel and hard electroless nickel are almost the industry standard.

References: Bosch Rexroth, Eaton, Stäubli, etc.

Applications :

- Pistons

- Covers

- Seal rings

- Hydraulic manifolds

- Connectors, etc.

Electroless nickel is often used on steel as an alternative to stainless steel parts which are expensive in terms of material and production. Electroless nickel is considered G.R.A.S. (Generally Recognized As Safe) by the FDA (Food and Drug Administration) and is therefore approved for use in direct contact with pharmaceutical or food products. Kanigen Group has a catalogue of compatible and non-compatible products that are available on request.

References: Pfizer, JBT Food, Procter & Gamble, etc.

Applications :

- Pill presses

- Bakery equipment

- Bottle and can filling machines

- Food and pharmaceutical packing machines

- Food transfer valves and transmission systems

- Pressure rollers for shaping the food prior to cooking, etc.

- Parts for high-end analytical equipment. For example for DNA research or virus detection.

Electroless nickel and its variants are applied in specialised machinery and equipment to provide additional properties and/or solutions on high precision parts or under specific circumstances.

References: Heidelberg, etc.

Applications :

- Paper printers

- Plastic film printers

- Injection and extrusion moulds

- Toolings and special jigs

- Transmission systems

- Pumps

- Valves, etc.

Electroless nickel and various variants are used by manufacturers of systems and components for gas, oil, on- and off-shore applications.

Kanigen Group is co-author of the NAM specification.

On request we can work in accordance with the application standards for diffusion layers.

The following standards can be applied:

Petrobras: ET-3000.00-1500-950-PMU-001

Technip: KA02

NOV : SP-ENG-004

Wellstream: MTL-5212

Schlumberger : ES40290

... .

Applications :

- Electroless nickel

Compressors, hydraulic components, ball, spool and butterfly valves, natural gas flow measurement components, lifting securing systems, submarine rudder rods, securing and fastening systems, rotary unions ... - Hard Chemical Nickel

Drilling systems, Heavy load lifting, ... - Electroless nickel with PTFE

Valve components, subsea ROVs - Diffusion electroless nickel

Hydraulic components and subsea couplings.

Our electroless nickel plating processes enable us to meet many of the needs expressed by the aerospace, defence and arms industries. The company's references include a number of prime contractors, arms manufacturers and equipment and vehicle suppliers.

Applications :

- Electroless nickel

Radar parts, missile parts, vehicle armour parts, screw-cutting machines for the manufacture of bushes and bush-filling machines. - Electroless nickel with PTFE

Machine gun and connector parts. - Black electroless nickel

Connectors, static parts integrated into armament systems, vision systems, front covers for casings and fixtures.

Textile machinery, which is heavily exposed to wear, contains many parts treated with electroless or hard electroless nickel.

References: Picanol, Vandewiele, Oerlikon, etc.

Applications :

- Power loom

- Yarn extrusion machines

- Winding machines

- Jacquard machines, etc.