Electroless nickel plus

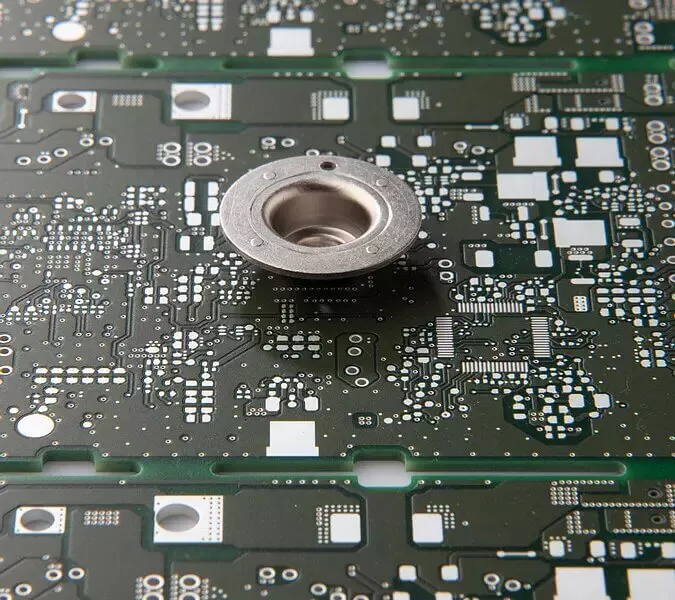

Kanigen Group has developed an automotive industry approved process that guarantees the solderability of electroless nickel, including suitable packaging for direct shipment to the assembly line, with an objective of having zero defects!

Bondability

Kanigen Group has developed a technique to maintain the surface wettability necessary for the automated soldering process.

This type of electroless nickel deposit, with its well-defined Phosphorus content, is particularly suitable as an under-layer for soldering.

Adapted processes ensure that the surface's wettability is maintained, even over time.

Generally, layers between 5 and 8 µm are applied.

Processed Materials

The electroless nickel plating process makes it possible to treat a broad spectrum of materials used within the industry. Kanigen Group primarily treats carbon, alloyed and stainless steels, cast iron, aluminium and copper alloys, etc., along with other more special materials such as silver (Ag), INVAR, 17-4PH, etc.

In recent years, we have specialised in the processing of all grades of aluminium, including not only the 1000, 2000, 3000, 5000, 6000 and 7000 series, but also die-cast and injected aluminium, with the exception of ZAMAK alloys.

Treatments are carried out in barrels, hang-plated or with dedicated fixtures/racks.

YES, I would like to receive more information regarding Kanigen Group’s technical solutions