Automotive

For over 25 years, Kanigen Group has been a valued supplier to automotive equipment manufacturers and their suppliers. To date, the group has been qualified by Continental, Bosch, BorgWarner, Valeo, Kendrion, JTekt, Gates, ZF, Hilite, Hitachi, Brink Towing Systems, CNH, Caterpillar, Dana, Cummins, etc. Further qualifications are ongoing.

Protection against corrosion

Wear-resistant

Non-magnetic

Reduced friction

Solderability

France

Automated line (barrel and jig plating):

- Low and non-alloyed steels

- Copper alloys

Belgium

- Automated line for non-alloyed steels (barrel plating)

- Automated line for aluminium (barrel and hang plating)

- Manual line (barrel and jig plating):

- Electroless nickel on alloyed steels

- NiPtef

- Low Phosphorus electroless nickel

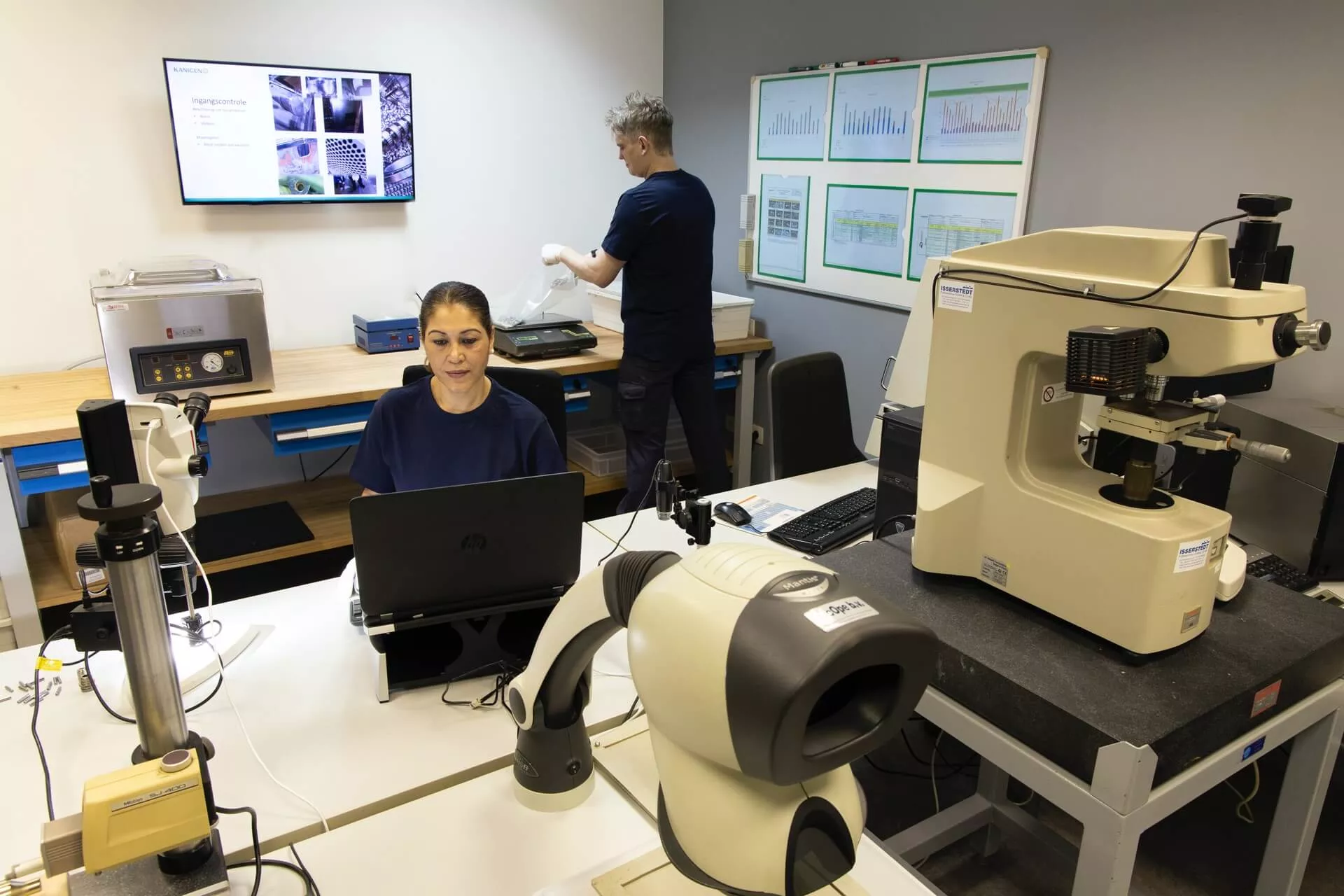

Our quality management system is ISO 9001:2015 certified and is supplemented by automotive manuals such as APQP, PPAP, AMDEC, SPC, MSA, etc., and by integrating applied techniques such as 8D, 5W, ISHIKAWA, Poka Yoke, etc.

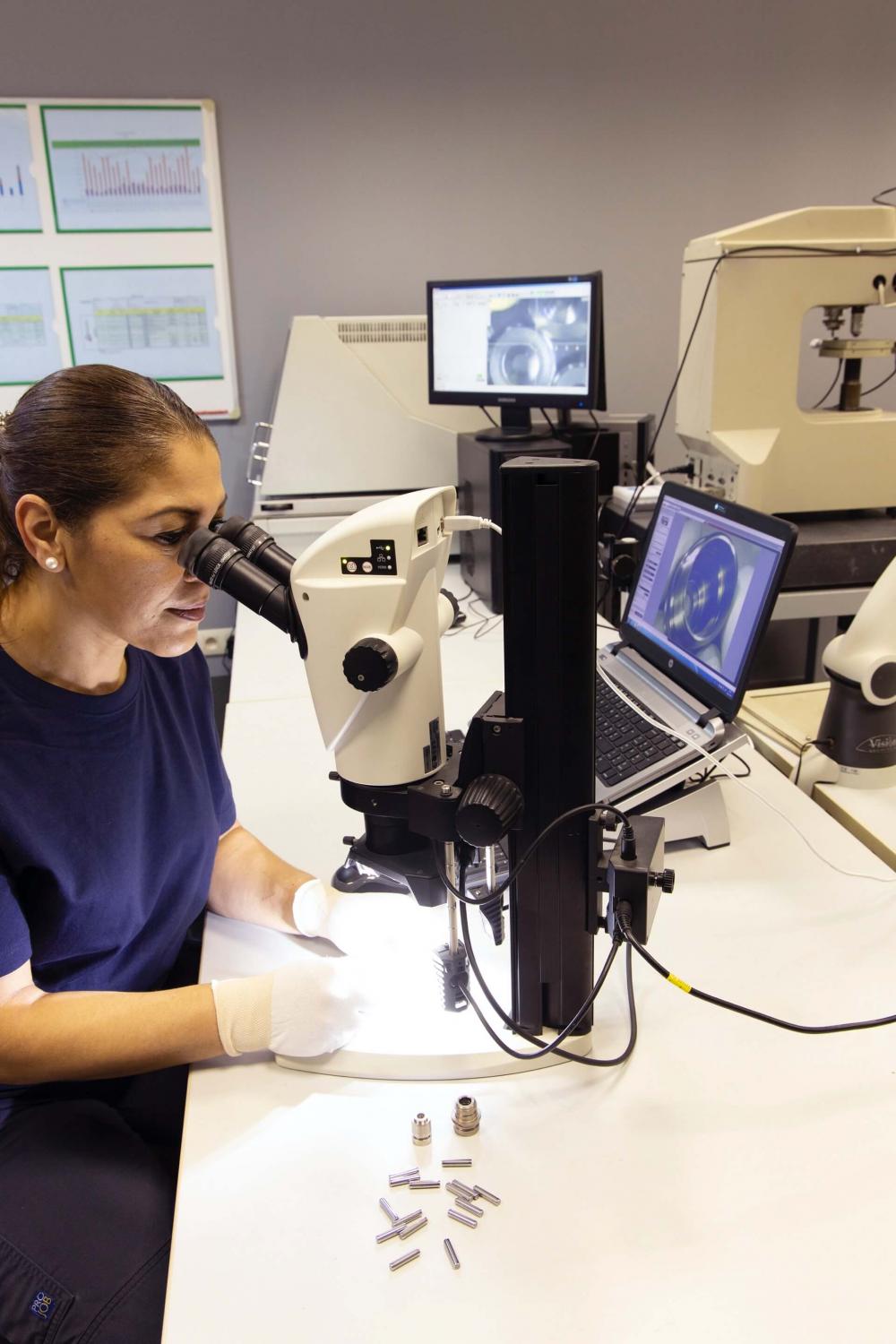

Our lab is equipped to make the following measurements:

- Thickness

- Adhesion

- Phosphorus content

- Binoculars (with integrated cameras)

- Hardness

- Porosity

- Solderability, etc.

We are present in many traditional applications such as engine valves, A/C, windscreen wipers, transmissions, towbar systems, differentials, ABS, ESP and damping systems, high pressure fuel pumps, etc.

Our teams are also involved in research and development surrounding new trends in electrification (e.g. IGBT cooling systems and heatsinks) or CNG and hydrogen pressure regulators, etc.