Hydrogen

Kanigen Group is involved in developments linked to the production of renewable energy and has been active on the hydrogen market for 15 years.

We support our customers in the BeNeLux, France, Germany and Scandinavia so that they can meet the many challenges they face, for both conventional electrolysers and PEM systems.

Corrosion protection

Amorphous

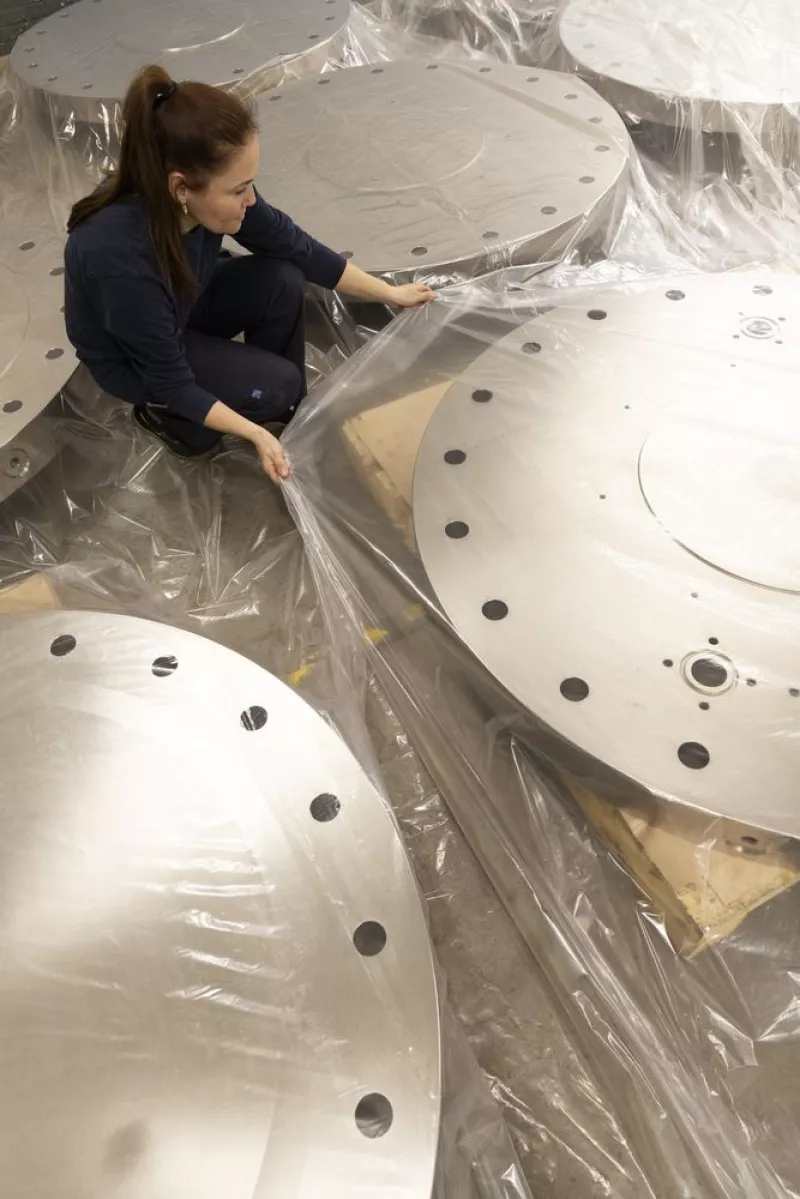

Recently, Kanigen Group acquired a new plating tank that meets the dimensioning requirements of the hydrogen sector. As this revolutionary market develops, we are investing in new production resources to meet expectations! At the beginning of 2024, a complete autonomous line will be operational to process this type of product.

Bath dimensions :

- Carbon steel: 3000 (Length) x 3500 (Depth) x 1500 (Width) mm

We are convinced that the Kanigen® process is a high-performance, green solution for the future.

That's why we work with our customers every day to help them meet the many challenges they face. We share our know-how with them to help them choose the type of electroless nickel best suited to their design or to meet their specific technical challenges, while of course guaranteeing total confidentiality with regard to their Research & Development work.

For example, we help them :

- optimize the design of components

- industrialize their products after the prototyping phase in order to reduce costs,

- improve their manufacturing methods to achieve the quality they are aiming for,

- formalize control methods and resources.

Today, we are proud to be working for these industrial pioneers:

- hydrogen production :

- Electrolyzer components

- Anodes, cathodes, collectors

- Electrodes,

- Separators

- Heat exchangers

- Piping

- PEM system components

- Electrolyzer components

- gas distribution and storage (high purity)

- the design/production of pressure regulators