Diffused electroless nickel

High phosphorous diffused electroless nickel plating is a Kanigen® electroless nickel deposit containing 10 wt% phosphorus (P). Following heat treatment >600 °C, a diffusion layer appears in the steel substrate resulting in:

- High corrosion resistance

- Excellent wear resistance under extreme working conditions

Underwater Environment

Diffused electroless nickel is designed to meet the most extreme requirements in terms of corrosion and wear resistance in a subsea environment.

Protection Against Corrosion

Thanks to its diffused layer into the substrate, the part remains protected, even after plastic deformation.

Wear-Resistant

The layer is abrasion resistant and, following the diffusion heat treatment with 750 HV0.1, its hardness is enhanced.

Reduced Friction

Diffused electroless nickel greatly reduces adhesive wear.

This type of deposit is generally used in (sub)marine environments to meet extreme requirements in terms of:

- Corrosion resistance (even after deformation)

- Wear resistance (abrasive)

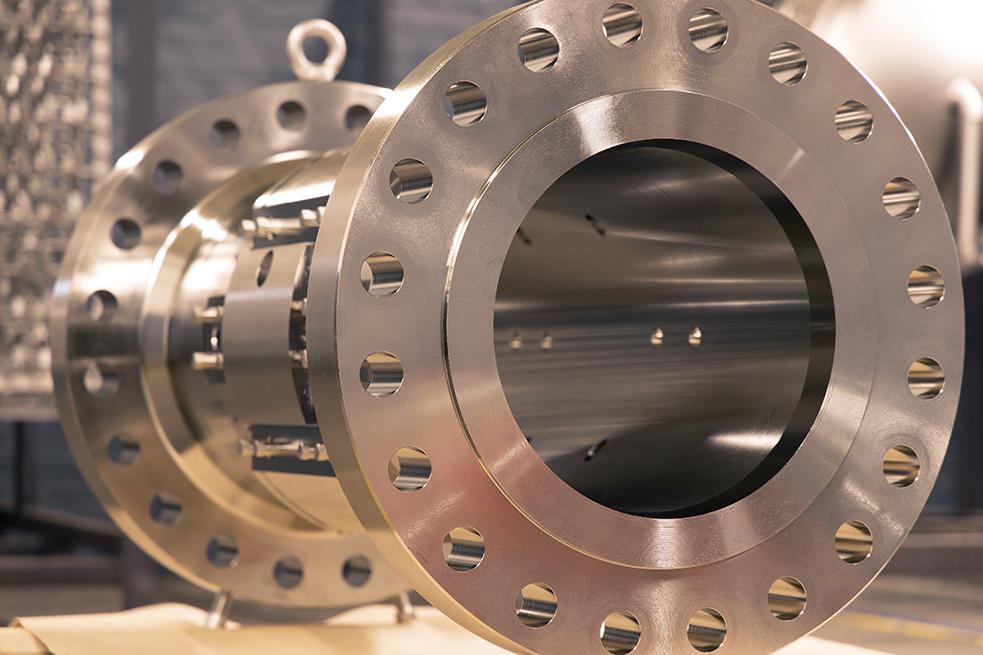

Applications :

- Natural gas flow measurement products

- On- and offshore

- (Sub)marine (subsea)

Processed Materials

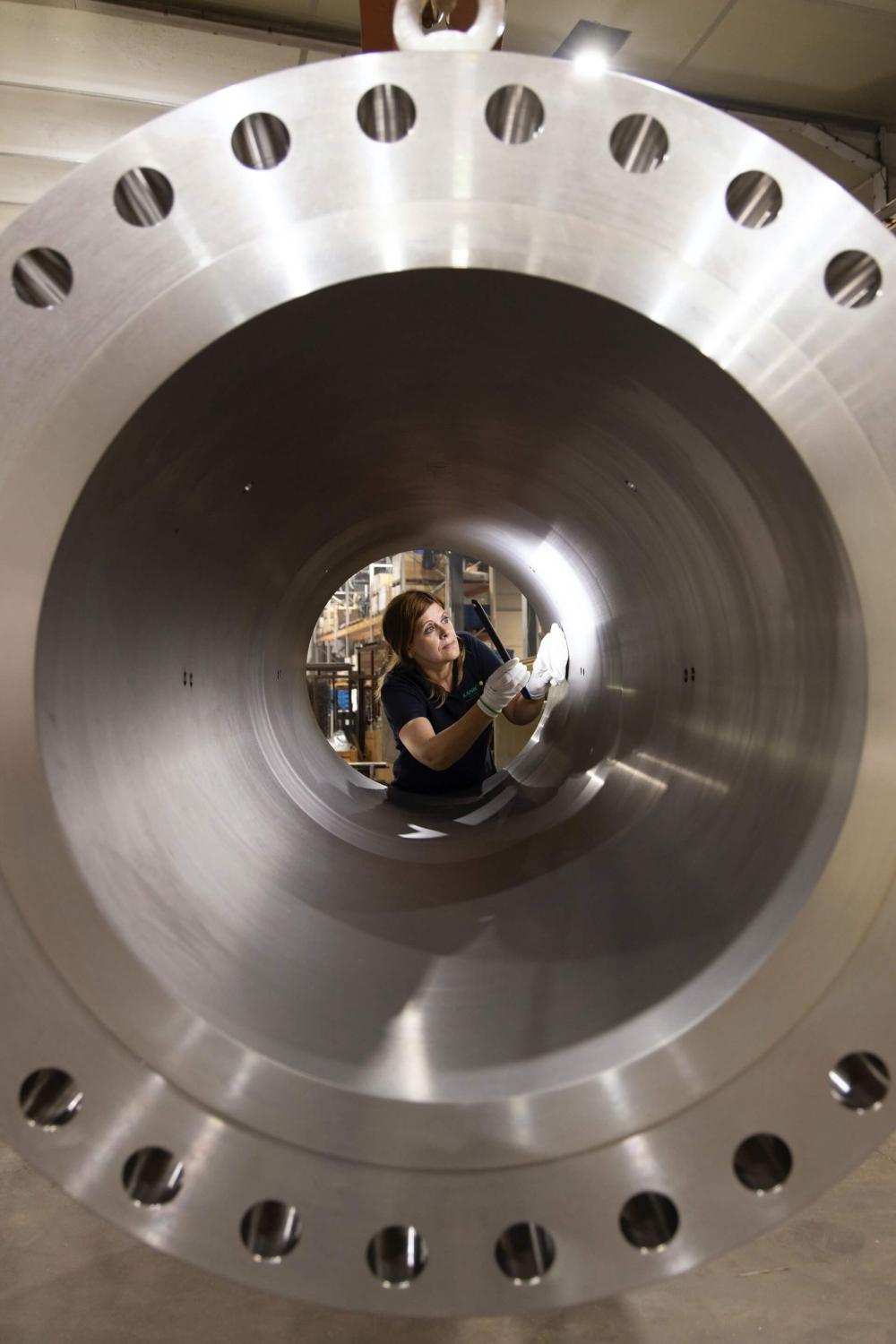

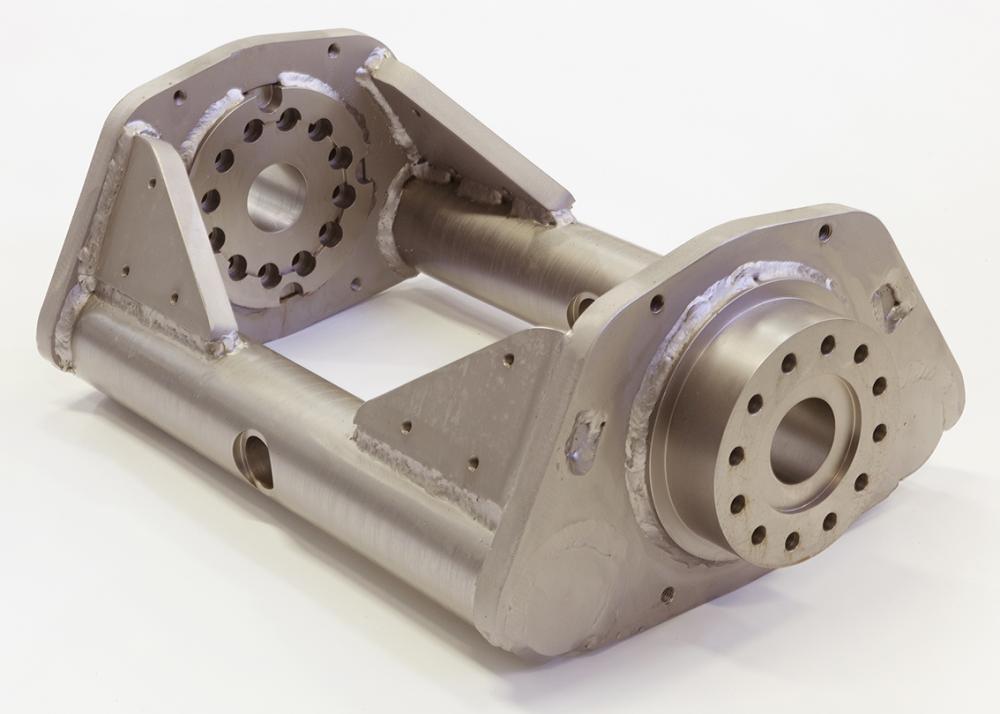

The electroless nickel plating process makes it possible to treat a broad spectrum of materials used within industry. Diffusion heat treatment is usually carried out on structural steel and cast iron. Some customers request its application on alloy steels.

Treatments are carried out in barrels, rack-plated or with dedicated fixtures. If appropriately designed and prepared, mechanically-welded equipment can also be treated.

Corrosion Resistance

Following the diffusion of the layer into the substrate, up to a depth of 2 to 4 µm (depending on the applied temperature and time), this layer becomes very resistant to corrosion, even following plastic deformation!

Technical Properties

- Contains 10 wt% P (Phosphorus).

- The deposit is under compressive stress.

- For a 75 µm layer, the diffusion layer depth obtained following heat treatment is 2 to 4 µm in structural steel.

- After bending over a mandrel at a 180° angle, until plastic deformation of the substrate (according to ASTM 571), the diffusion layer does not show any cracks.

- Hardness following diffusion heat treatment: 750 HV0.1.

Diffused electroless nickel

YES, I would like to receive more information regarding Kanigen Group’s technical solutions

Download the data sheet