News

New pretreatment line for aluminum

Kanigen Works Benelux has invested in a new pre-treatment line for electroless nickel plating of aluminum in order to also be able to handle parts with large dimensions (2600 x 2050 x 1000 mm).

In addition, to meet specific customer needs with regard to purity, an investment in a clean room of 4.5 x 7.5 m will be implemented. Purpose: to optimize the final inspection with UV light in order to remove all visible particles before packing the parts.

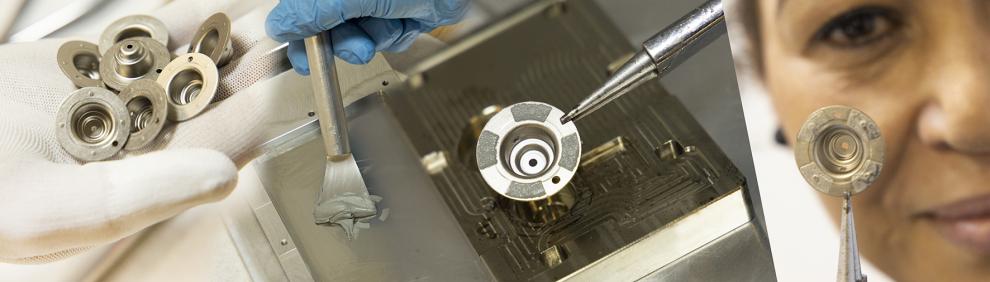

Following a new project for the automotive sector, in which the components must be soldered after electroless nickel plating, Kanigen has developed a process to permanently guarantee the good wetting of the surface, and implemented adapted packaging techniques to ensure absolute and consistent quality.

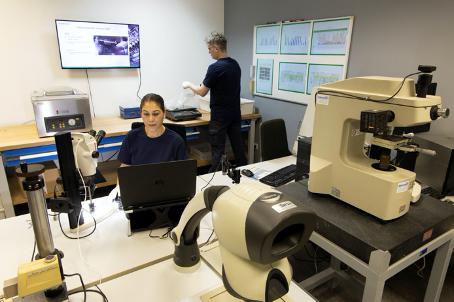

Finally, Kanigen Works Benelux has invested in a more spacious and better-equipped quality lab.