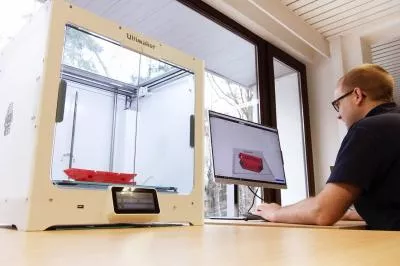

Engineering Solutions

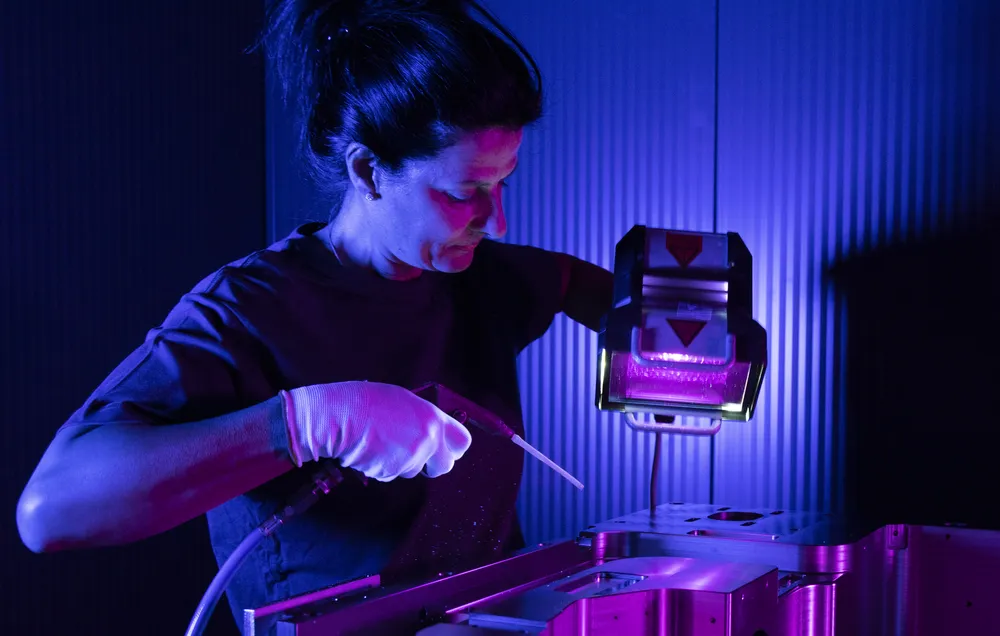

Entrust your project to our teams of experienced technicians and engineers, providing optimised and efficient solutions.

Electroless Nickel on Aluminium

Have you ever considered electroless nickel plating for your aluminium parts or components? There are a whole host of benefits that are not to be missed!

Qualified Automotive Processes

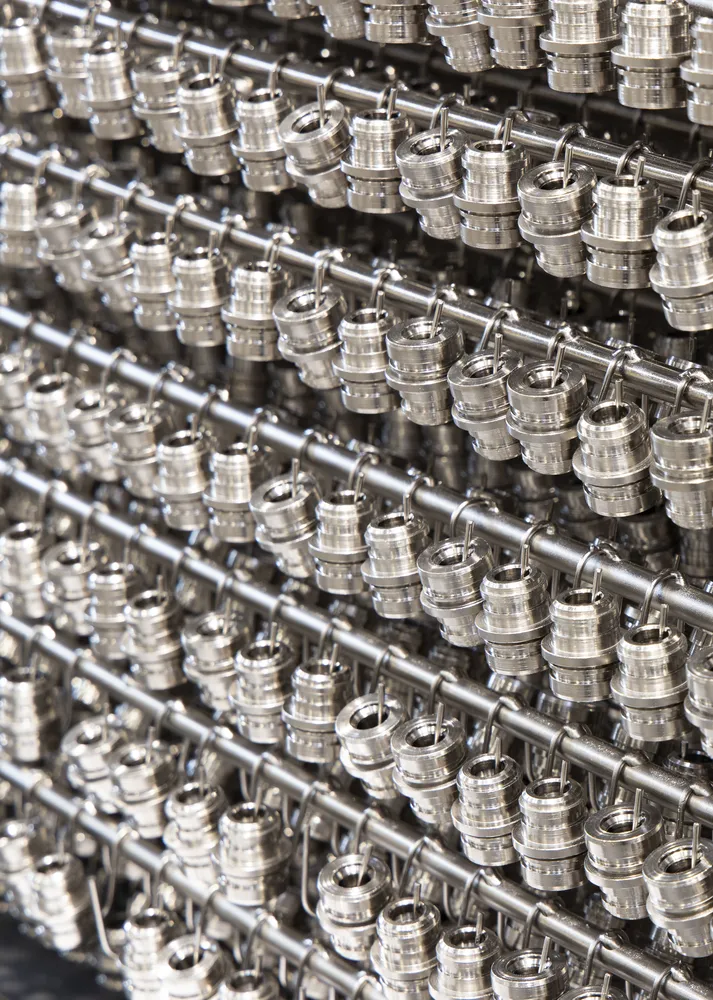

Did you know that our automated lines have been approved by the automotive industry? Over the years, we have developed a real know-how for this challenging market.

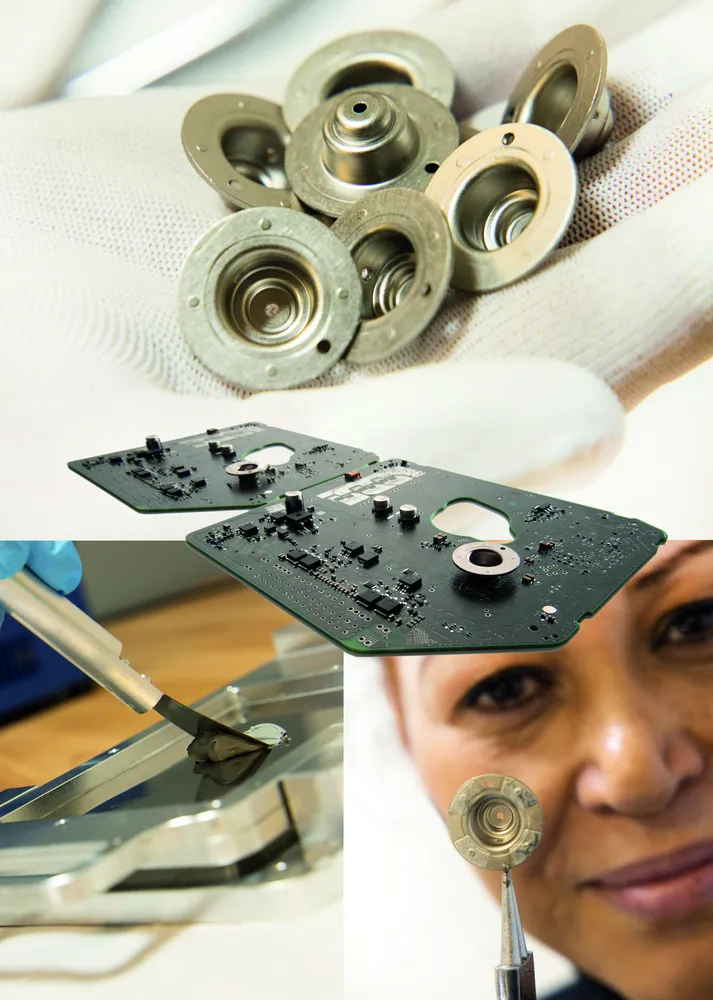

Solderability

Are you familiar with the soldering process on electroless nickel plating? What new properties can this innovation of Kanigen Group bring to your parts and/or equipment?

Completely Uniform Coating, Very Precise and Without Edge Effects

Kanigen Group specializes in metal surface treatments and is now one of Europe's leading electroless nickel plating companies. The group has two complementary production units in France and Belgium.

Kanigen France in Bonneville

In 2007, Kanigen Group set up its surface treatment plant in Bonneville, close to its bar turning customers, in the heart of the Alps.

Kanigen France focused on the surface treatment of technical parts for the automotive market, including parts for engines and transmissions.

Today, its future lies in the ecological transition. The company is currently positioning itself in emerging markets such as e-mobility and electric vehicles.

Kanigen Works Benelux in Genk

Kanigen Works Benelux was founded in 1959 in Genk, in the industrial heartland of Limburg. At the time, we were one of the few pioneers in electroless nickel plating in Europe.

Today, Kanigen Works Benelux focuses on the processing of technical parts for growth markets such as semiconductors (stepper-wafer-machines).

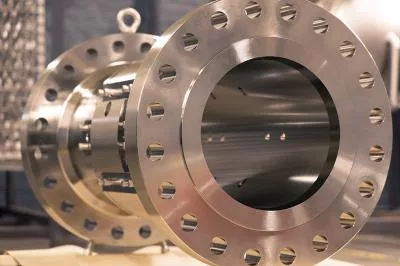

Kanigen Works Benelux also specializes in electroless nickel plating for the hydrogen production market and in the treatment of aluminium parts, including parts for power electronics for the automotive market, as well as very large parts.

Kanigen France in the heart of the French Alps

C-mine in Genk, the redeveloped former mining site