Electroless nickel with ptfe (NiPtef)

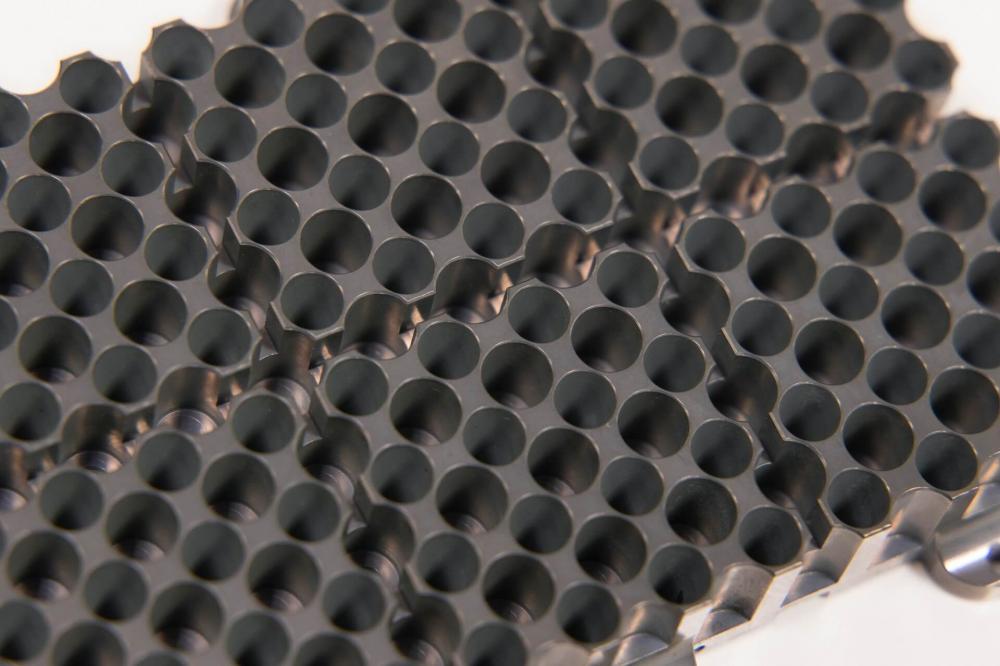

NiPtef is a co-deposition layer of Kanigen® electroless nickel as a sublayer and a composite (dispersion) layer of electroless nickel with PTFE.

This process gives the treated parts specific and functional characteristics: hard, self-lubricating and hydrophobic.

Reduced Friction

Hard, self-lubricating and hydrophobic layer.

Wear-Resistant

The hardness of the layer can be increased via heat treatment.

NiPtef is a layer made up of Kanigen® electroless nickel, followed by a co-deposition layer of electroless nickel and PTFE.

During the NiPtef layer's deposition process, PTFE particles with a diameter of 0.2 to 0.3 µm are embedded in the electroless nickel layer in a homogeneous manner.

By incorporating a dry lubricant, PTFE, combined with hard electroless nickel matrix, electroless nickel with PTFE is an excellent alternative to the problem of wear and friction between two surfaces. With values of order of magnitude of 0.05, PTFE offers a low coefficient of friction.

Unlike synergetic PTFE deposits, the friction coefficient remains constant in the event of layer wear thanks to the homogeneous distribution of PTFE within the NiPtef deposit.

Processed Materials

The electroless nickel plating process makes it possible to treat a broad spectrum of materials used within the industry. Kanigen Group primarily treats carbon, alloyed and stainless steels, cast iron, aluminium and copper alloys, etc., along with other more special materials such as silver (Ag), INVAR, 17-4PH, etc.

In recent years, we have specialised in the processing of all grades of aluminium, including not only the 1000, 2000, 3000, 5000, 6000 and 7000 series, but also die-cast and injected aluminium, with the exception of ZAMAK alloys.

Treatments are carried out in barrels, hang-plated or with dedicated fixtures/racks.

Corrosion Resistance

The electroless nickel and PTFE deposit constitutes a porous (dispersion) layer.

The Kanigen® electroless nickel layer is used as an under-layer to protect from corrosion, while the thickness is determined by the customer's specifications. A side effect of PTFE's hydrophobic character is to reinforce this property.

Technical Properties

- PTFE content min. 20 V%.

- Friction coefficient:

| Unlubricated | Lubricated | |

| Steel vs steel | grip | 0,20 |

| NiPtef vs steel | 0,15 | - |

| NiPtef vs Kanigen® | 0,10 | - |

| NiPtef vs NiPtef | 0,05 | - |

- Hardness

- As deposited 350 HV0.1*

- Hardness following heat treatment 550 HV0.1*

- Non-stick coating

- Water- and dirt-repellent

(*) Mixed hardness (Vickers and Shore) measured in HV0.1 on 50 µm NiPtef-treated control plate.

The residual energy of an electroless nickel layer with PTFE, with about 20-30 V% PTFE, is up to 18.6 mN/m. As a result, parts treated with NiPtef have excellent non-stick properties.

Current Standards

These treatments are carried out according to European standard ISO 4527 or, more specifically, according to AMS 2454.

Other standards can be followed on request.

YES, I would like to receive more information regarding Kanigen Group’s technical solutions