Hard electroless nickel

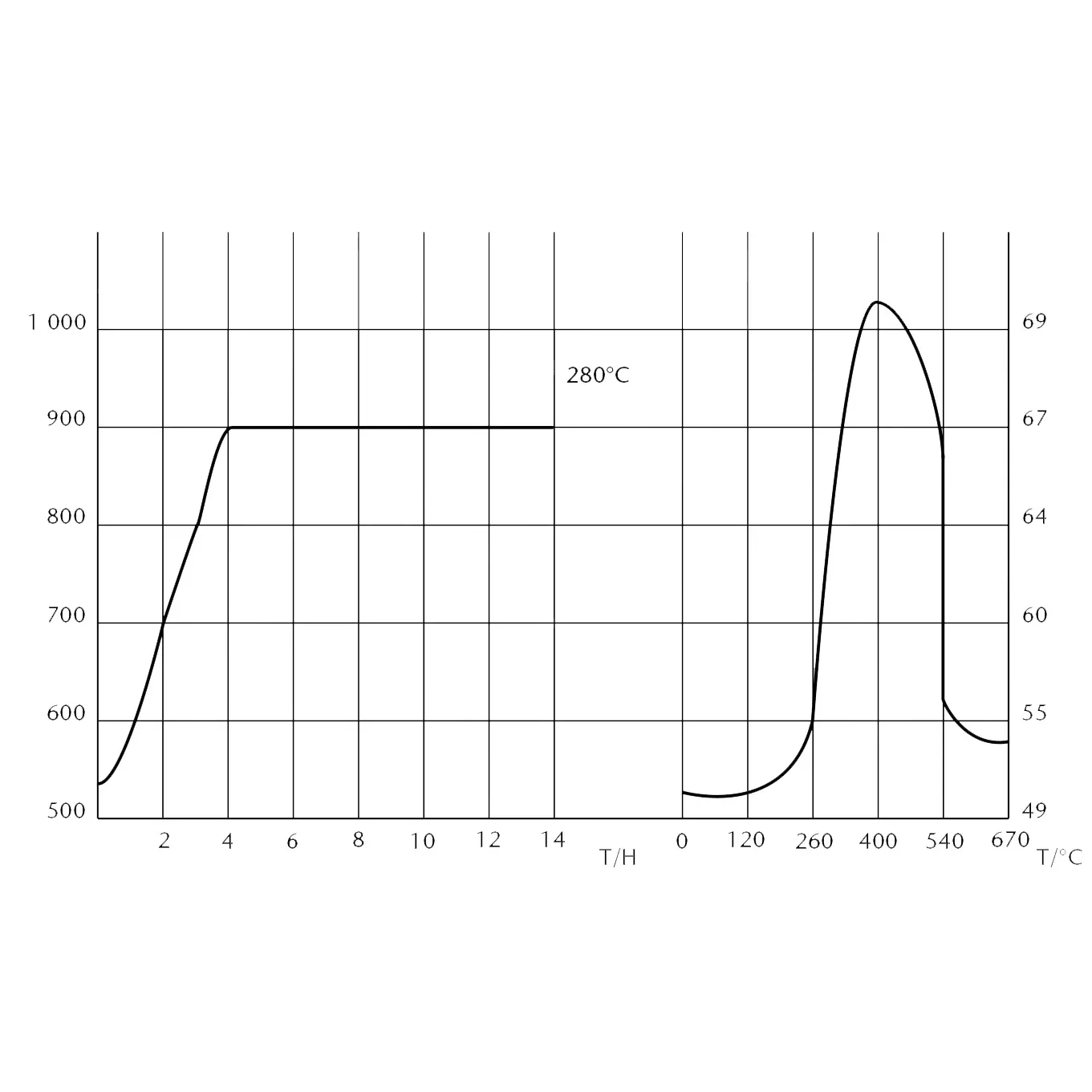

Hard electroless nickel plating is a layer of Kanigen® electroless nickel (9-12 wt% P) that has been heat treated/received a heat treatment to obtain a hardness of >900 HV0.1.

This heat treatment alters the structure of the layer from an amorphous structure to a crystalline structure. Following this recrystallisation, depending on the chosen time and temperature, its hardness increases.

Wear-Resistant

Following heat treatment of the electroless nickel layer, its hardness reaches >900 HV0.1

Reduced Friction

Hard electroless nickel greatly reduces adhesive wear and is also used to prevent galling.

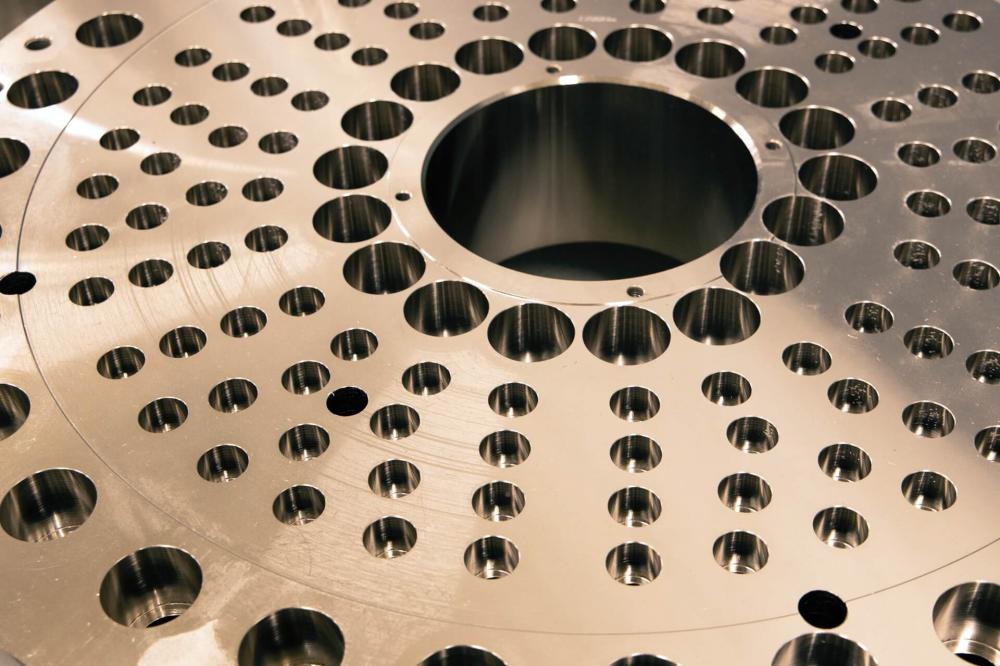

This type of deposit is used in applications where wear resistance is paramount and, in some cases, can serve as an alternative to hard chrome.

- Differential pins and washers

- Machine parts for glass, paper, food, textile industries

- Oil rig clamps

- Valve spools

- Rear freewheel hub on a bicycle

- Gearbox splines for industrial vehicles

- Motor valve fittings

- Hydraulic cylinder parts

- Couplings

- Flanges, etc.

Treated Materials

The electroless nickel plating process makes it possible to treat a broad spectrum of materials used within the industry. Kanigen Group primarily treats carbon, alloyed and stainless steels, cast iron, aluminium and copper alloys, etc., along with other more special materials such as silver (Ag), INVAR, 17-4PH, etc.

In recent years, we have specialised in the processing of all grades of aluminium, including not only the 1000, 2000, 3000, 5000, 6000 and 7000 series, but also die-cast and injected aluminium, with the exception of ZAMAK alloys.

Treatments are carried out in barrels, hang-plated or with dedicated fixtures/racks.

Treatment Options

- Two treatment options are available:

- At 280 °C, to obtain a hardness of 900 HV0.1

- At 400 °C, to obtain the maximum hardness of 1,100 HV0.1

Electroless nickel is typically applied to complex geometries. Given that the part's accuracy is important, deformations resulting from heat treatment must be avoided. Kanigen Group has therefore opted for the treatment at 280 °C.

Caution! Using heat treatment to harden the layer may have an effect on:

- Weld tensions

- Aluminium mechanical properties

- An alternative for Hard Electroless Nickel can be a low phosphorous electroless nickel deposit, as plated : hardness >750HV0,1

- The tempering temperature of hardened steels

Technical Properties

- Hardness: 900HV0,1

- Reduces friction

- Reduces

- Adhesif wear

- Tribochemical wear

- Rolling wear

- Abrasion (time-limited) wear

- Prevents galling

- Avoids cold welds

YES, I would like to receive more information regarding Kanigen Group’s technical solutions